Structural Insulated Panels

We provide energy-efficient building solutions for commercial, residential and industrial construction projects. Explore the versatility, strength and energy efficiency of structural insulated panels (SIPs), compared with traditional construction methods.

-

Faster

SIPs arrive at the job site pre-cut and ready to assemble, making framing time more efficient so you can finish your project faster.

-

Stronger

With proven long-term resiliency and versatility to support almost any design, SIPs are the answer for builders and designers everywhere.

-

Greener

From factory fabrication to the completed project, SIPs are a sustainable building solution at every step.

Build For The Future

As we work towards a more sustainable future, it becomes increasingly important to make smart building decisions. Structural insulated panels are the innovative, high performance solution for modern challenges.

West-Eco combines many years of in-house pre-panelized building component consulting, design, project management, and assembly experience with North America’s largest and most recognizable SIP manufacturer as a supply partner, Premier Building Systems.

A key component of the upcoming comprehensive new building code requirements for residential construction is more stringent requirements for energy efficiency in walls and ceilings, and by enclosing your home with SIPs, it’s an easy way to meet those requirements. Plus, SIPs combine a firm wall, exterior sheathing and hearty insulation into one step, making the installation quick and easy.

SIPs Versatility

Structural insulated panels are adaptable enough to be used in almost every project, industry, and location.

SIPs Building Panels are Used When:

• A high performance, energy efficient, framing solution is required

• The builder needs to improve timeline to “lock up” phase

• Worksite is in a remote location. Panelized building systems reduce transportation costs and waste

• Transportation to the site is limited

See the versatility of West-Eco and SIPs by clicking the links below.

Implementing SIPs

For more than 50 years, SIP roofs, walls and floors have framed homes from the ocean front in Western Canada, to hot temperatures in Southern Florida, to freezing winters from Alaska to the Yukon. Anywhere in the world, SIPs can be used to create a strong, innovative high performance structure.

Walls

The rigid foam core inside each SIP provides continuous insulation across the panels’ width and length, avoiding the thermal bridging created by wall studs. Also, because SIPs building panels come prefabricated in large sizes (up to 8’x 24′), SIPs have significantly fewer joints that require sealing. Blower door tests find that rooms built with SIPs have significantly less air leakage than stick-framed spaces. Whole-wall R-values of SIP walls versus stick framed walls are much higher when taking into account energy loss through the structural members, corners, joints, and around windows.

Roofs

One primary benefit of SIP panels in roofs is their long clear-span capability. The large, single-piece panels can typically span up to 20 feet, reducing the need for interior columns or other intermediate structural supports. Design professionals also can use SIPs in roof structures without an engineered truss system. These capabilities work well for vaulted ceilings, large open spaces, and soaring rooflines, which are common in schools, lodging facilities, multi-housing, and other institutional and commercial building designs. One application that has been growing in recent years is incorporating SIPs as part of living roofs. Because SIPs can accommodate high loads from soil, plants, and water, and have fewer gaps than other roof-framing methods, SIPs can help meet the challenges of a green roof

Floors

Although less common than wall and roof applications, designers can also use SIPs in floor structures where they are not supporting load-bearing walls. Additional support below any load bearing wall is required. SIPs are most commonly used where an insulated floor system is required, such as when building on piers or pilings or other unheated areas.

SIPs Panels: Key Benefits

With benefits like these, it’s obvious that SIPs are the superior choice for your next building project.

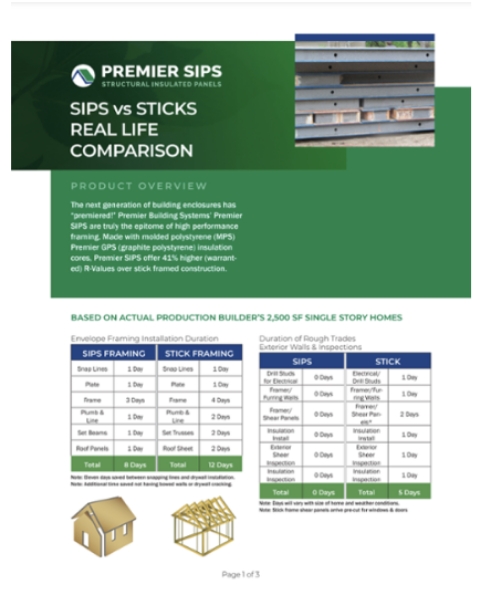

Quick & Easy – Depending upon the size and design of a home, it can be enclosed with SIPs within days or even hours. This saves money on labor, insurance and financing, as well as energy on the job site.

Flexible – SIPs can arrive at the home site and the panels will be cut exactly to the home’s design at our factory, then numbered for easy installation, which results in less wasted materials and resources.

Energy Efficient – SIPs cut heating and cooling costs by as much as 60 percent over products used for conventional “stick” construction. Even where wall thickness is the same, SIPs outperform stick framing on whole-wall energy performance by 40 to 60 percent, according to a study by Oak Ridge National Laboratory.

Soundproof – SIPs block sound like few other materials — a big perk, especially in bedrooms, dens, home offices and media rooms. This due to the solid construction and lack of air transfer,

Environmentally-Friendly – Components that comprise SIPs come from renewable resources. The insulation is a form of plastic, and oriented strand board (OSB) is made from fast-growing trees and shrubs once considered waste by the lumber industry.

Air Tightness – SIPs are one of the most airtight and well-insulated building systems available, allowing for better control over indoor environmental conditions. Reduced energy consumption for heating and cooling throughout a building’s life is SIP’s most substantial contribution to preserving the environment.

Why Choose SIPs?

SIPs are superior in comparison to traditional 2×6 lumber framing methods.

| Benefit | 2X6 R19 (Fiberglass) Construction | SIPS Construction |

| Energy Efficiency | Baseline | Up to 48% more efficient |

|---|---|---|

| R-Value | Baseline | Whole wall SIP assemblies significanlty out perform a 2X6 R19 wall and offer a 20-year thermal warranty. |

| Labor Costs | Baseline | Up to 55% labor savings. Proven! |

| Strength | Baseline | 20-30% Stronger - SIPs handle higher in-plane compressive loads. View Load Charts |

| Seismic | Tie downs and additional material/labor costs required to meet code | Approved by code in all seismic zones, additional tie downs may be required depending on design |

| Waste Created | Baseline | 30% less salvageable structural lumber sent to landfills over sticks. Premier SIPS are recyclable and made with recycled content. |

| Fire Resistance | Sticks require one layer of 5/8" drywall to meet a 1-hour fire wall approval | Premier SIPS are code approved for multiple 1-hour wall assembly options. |

| IAQ - Indoor Air Quality | Baseline, no IAQ certification | Clean air gold certified. |

The Cost Advantages

SIPs are efficient, sustainable, and can save you costs on your build and in the long-term.

-

40% Savings

Tighter buildings means smaller HVAC systems

-

Finished Faster

Buildings are completed within less time

-

$0 Insulation Costs

SIPs are pre-insulated so you don’t need additional insulation

-

Less Waste

30% less waste when building with SIPs then other building solutions

Resource Guides

Take a look through our various brochures to learn more about SIPs, their functionality, and how to effectively build with them.